ú��������������ת�������о�

����ΰ����˧�棬��������������

(������ú̿���Ž���ú������ ���� 719315)

��ú���������У��ڱ��������ڡ�Χѹж�ء�����ж�صĹ����а�����������ת�����ͷţ���ú�����������ú���е���������Բ������R0Ϊ������Զ��������ĵķ���ת�ƣ�ͬʱ��ת�ƹ����л�������������ͷš�������ת�Ʋ���ʱ����ʹ������ú��������ﵽú�����ܳ��ܵļ����������Ӷ�����ú���������������������ֺ������������ھ�ˮѹ��״̬�£���ú������ú����Ӧ����״̬�����ƽ���ԭ��Ӧ����ת��Ϊ���·ֲ��Ķ���Ӧ��״̬���ڶ���Ӧ��״̬�У����ڿ�����ú�����Ҹ����������ϴ��������������Χ��ú��������Ƚ�������״̬��Ҳ����ͨ������ġ��������ˡ�����ú���Զ���������ܵ���С����Ӧ�����С��ú����ܵ�Ӧ����С�����Ի��ɿ�ʼ�ġ�����״̬��ת��Ϊ֮��ġ�����״̬�������䴦������״̬�µ�ú�����Ҫ����֧������ֹú���������ú���׳���Σ����������õ�������ѧ�����������Χ�ҽ����������뵯�����������㣬ȷ�����������ķ�Χ�������������Ӧ����Ӧ��������������غ�Ƕȳ������о���������Χ�ҵ�����ת�����ɣ���������ƽ�ⷽ�̣�������������Χ�ұ���ʧ�ȵĻ�����

��������ɢ�뵯��Ӧ���ܵ�ת�������о��ϣ��ܶ�ѧ�߶������˴����о���������[1]�ó�����Χ�������ܵ������Ӧ�������ӣ����ͷŵ���Ӧ���ܺ�������ɢ������Ӧ�����Ӳ��ҵ�����������ʯ������ɵ������������ʱ�����������ת�ƺ��ͷţ�

������[2]����������˵����۹�ʽ�Լ�����������ֵ�ļ��㷽����ͨ���ֱַ�������ϵĵ����ܡ������ܡ��������Լ��ѱ��ܸ��Զ�Ӧ���������ֱ��ӦΪd��e��d��p��d��r��d��f��ͨ����������d��=d��e+d��p+d��r+d��f������ϵı���������

л��ƽ��[3]�ó�������ɢ�������ͷ��ǵ���ʯ�����ƻ��ĸ���ԭ��ͬʱ��ʯ�ڶ�̬�����뾲̬���ص�Ӧ�����������������ģ�

�����Ƶ�[4]�Լ���������Ϊ�Ա���������ɰ����ѭ�������غ������£�ɰ���ڲ��Ŀ��ͷŵ���Ӧ���ܺ���ʯ��ɢ��֮�������ת�������о����ó��������ʶ�ɰ�ҵĵ���ģ���Ͳ��ɱ�Ӱ�첻�ɵ���Ӧ��������ʯ��ɢ֮�����ż������ʵ��½������ͣ�

�ƴ��[5]�Դ���ʯΪ�о����ϣ����ҿ��Ƽ���Ӧ����������о������ҵ�������ɢ���ͷŵĹ��ɣ��ó��ڼ�������С��ijһ����ֵʱ����ʯ����Ϊ��������״̬��ͬʱ����ʯת�������У�ת�����������Ӧ������һ��������Բ�����ʯ������Խ���ͷŵĵ���Ӧ����Խ�ߣ�

��躵�[6]�о������ڲ�ͬΧѹ״̬������ת���������������˹��ɣ��ó���ΧѹӦ���ϵ͵�����£�ΧѹӦ��Խ�ͣ���������Խ���Ǻ�ɢ��ȴԽ�ͣ���֮�෴������ͨ������֮�Ƚ���ʯ����Ϊ3���Σ���3���η�ӳ��Χ����ж�ɹ����������Ļ��ۺ��ͷŵı仯���̡�

�����ʼӦ������������Ӧ��ƽ�⣬�����������ж���ƻ���ԭӦ��ƽ��״̬��ʹΧ��Ӧ�������·ֲ�ʵ�ֶ���ƽ�⡣��ģ����Ҫģ����ú���������У��������rΪ�����γɵ����Է�����Ӧ���ֲ����ڿ������Ҹ�����ú�����Ȼ���ֱ��������������γ����Էֲ���Ȼ�����γɵ��Էֲ�����ģ��ּ�ڽ�����ˮѹ��״̬��ú��������������ƽ�ⷽ��[7 -12]��

��ʵ�������У��������Ӧ���������Ӷ�����ܹ����Ŷ�Ӱ�죬��������ѧʽ�������Χ�ҵ�Ӧ���ֲ��������ˣ�������ģ�������¼���裺�����Χ��Ϊ���ʡ�����ͬ��ú�塣���ں�ú��������ԣ�����������ú�����Χ�Ҿ���ú�壬������ͬ����Ҫ��

����һ��������������£����������������ģ�ͼ�Ϊ��Գ�ƽ��Ӧ���������

�۽�ϵ�Ч���������������ΪԲ�Σ����Ч�뾶Ϊr��

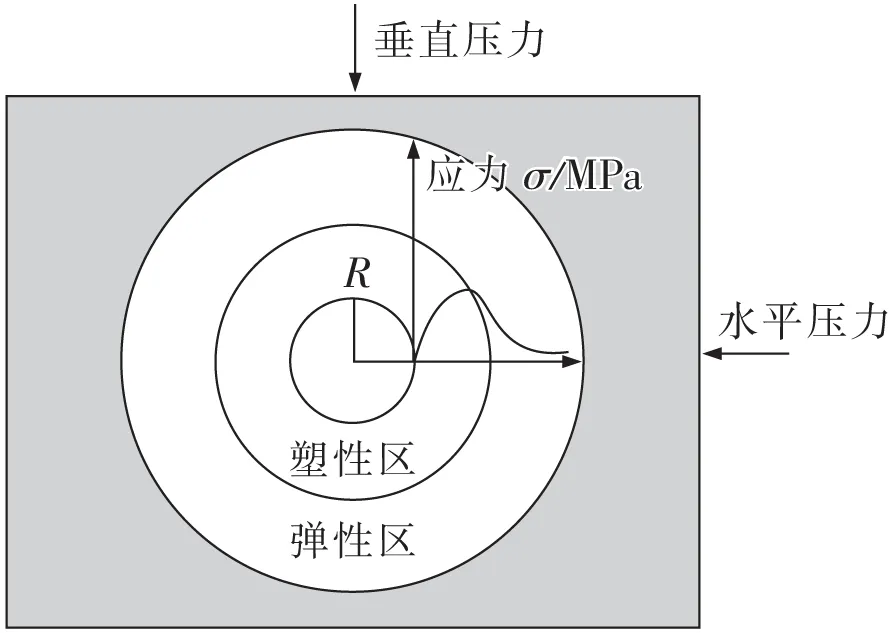

��������Χ���ؾ�����dz��������γ��������������������뾶�ֱ�Ϊr�ܺ�r������r>r����Ϊ��������Ӧ���ֲ�״̬��ͼ1��ʾ��

ͼ1 ú���������е�Ӧ���ֲ�״̬Fig.1 Stress distribution state during coal roadway excavation

1.1 �����������̵Ľ���

�ھ�ˮѹ��״̬�£�ú����֮ǰ��ú�����ܵ���Ӧ��ֵΪ�������״̬������10=��20=��30=��h(h=���ɵ����)��

����������֮ǰú�崢�����������Ϊ

��Ϊ�����ǵ����Ϊ��ˮѹ��״̬�£�����Χѹ2�����������ȣ���

1.2 �����������������̵Ľ���

�������������̵Ľ�������Χ�ұ�����Χ�����˵������У�Χ�ҵ��������ͷű�������Χ���ƻ�����Ҫ����Դ���ɱ�ʾΪ

(1)

ʽ�У�reΪ����ij����������ľ���(3��5r0)��

���е�����Ӧ������Ϊ

(2)

(3)

�������İ뾶����Ϊ�����������뵯�����ı߽紦������Զ��(ʵ����ԭ��Ӧ��Ϊ5%���ң���3��5r0)

��������Ӧ���ϵʽ

(4)

1.3 ��������ɢ�������̵Ľ���

Χ�����������ͷű�����Ϊ��ʽ

(5)

������������Ӧ������Ϊ��ʽ

(6)

(7)

�������İ뾶����Ϊ��ʽ

rp=

(8)

��������Ӧ�乫ʽΪ

(9)

��ˣ����Χ�������ķ��̿�����������ѧ��������Ϊ

(10)

���ʵ�ʣ�����������Χ��Ӧ���ֲ���ѧģ�ͣ������������Ƶ�Χ�ҷ���(�������͵�����)�뾶��Ӧ�����������̡�����������Χ��Ӧ���ֲ���ѧģ�ͼ���ؼ��裬���õ�����ѧ�Ƶ�����ж�����ݵ�Ӧ���ֲ���ʽ��

�������Χ��Ӧ���߽�������Ӧ�������������Ƶ��˸�����������Ӧ���ֲ���ʽ�������������������Χ�Ҵ���Ŀ��ͷű����ܱ���ʽ��������������������

������������ƽ�ⷽ�̣�����Ӧ��ģ�ͽ�����������������ƽ����ơ�

����ּ��̽����ʯж�ɹ����е���ѧ���Ժ������ݻ�������������Ҫ�ӳ���������ء�����ѹжΧѹ����Ӧ���Ŷ�жΧѹ3����չ�������б���ѹжΧѹ������������ѹ2����ʽ�����鷽������1���������ᡢ����ѹжΧѹ��ж��·����ͼ2��ʾ��

��1 ���鷽��

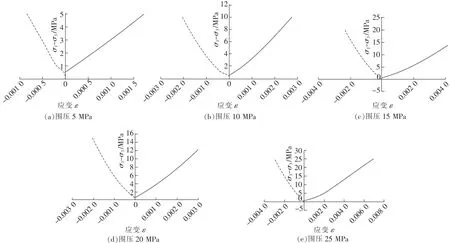

���������ݵ��뺯����ͼ����Origin���д����������ó����¹��ɡ���ͬΧѹ��Ӧ��Ӧ��������ͼ3��ʾ��

3.1 Χѹ��ú�崢������

��������=��ѹ����+Χѹ�������ֱ��ΪW1��W2����Ϊ��ѹ����������Ӧ��Ϊѹ���ܣ�Χѹ����������Ӧ���Dz������ͱ����ܡ�

������ϰ����������Ҫ�졣�������ɣ��⻰�����ʱ���ã��ڸ���ϰ��ͬ�����ã�����Ҫ�����˼��Σ����������ô����ƽ�⣬��ô�ƶ�������������������Ҫ�ѵö࣬�������̸����ǵĻ�ֻ��һЩ��������ʽ��ɳ��Ū���ҵ��ֽ����ˣ�Ƥ��Ҳ�����ˣ���������ô������������˿������������Ʈ����ȫ�ǻ���ɳ����������

�ɹ�ʽ�ɵã���ѹ��Ӧ������ΪҲ���Ǵ�ֱ��������ú�����Ĺ���W��=0.846 249 553 7 kJ��0.85 MJ��Χѹ����Ӧ������Ҳ����ˮƽ��������ú�����Ĺ���WΧ-0.288 988 294 4��-0.29 MJ��

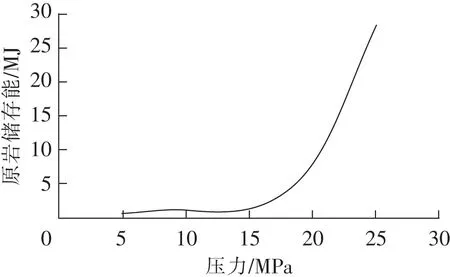

����ΧѹΪ5 MPaú�崢������ΪW��=W��+2WΧ=0.56 MJ��ͬ��Χѹ10 MPa��15 MPa��20 MPa��25 MPa���������ֱ�Ϊ1.09 MJ��1.27 MJ��7.8 MJ��28.3 MJ��

�����ھ�ˮѹ��״̬�²�ͬΧѹ��ú�崢�����������2��

��2 ��ͬΧѹ��ú�崢�������

������Χѹ�仯��������ͼ4��ʾ��

ͼ2 �������ᡢ����ѹжΧѹ��ж��·��Fig.2 Conventional three-axis��loading and unloading path of lifting axial pressure and unloading confining pressure

ͼ3 ��ͬΧѹ��Ӧ��Ӧ������Fig.3 Stress strain curves under different confining prssure

���ݲ�ͬ��Χѹ��ú���Ӧ�������ɵã�ú�崢���������Χѹ(����)Խ��������Խ����������仯����Խ�죬��ʵ��ú�������еĹ��ɴ�����ͬ��

3.2 ж���������������ͷ�

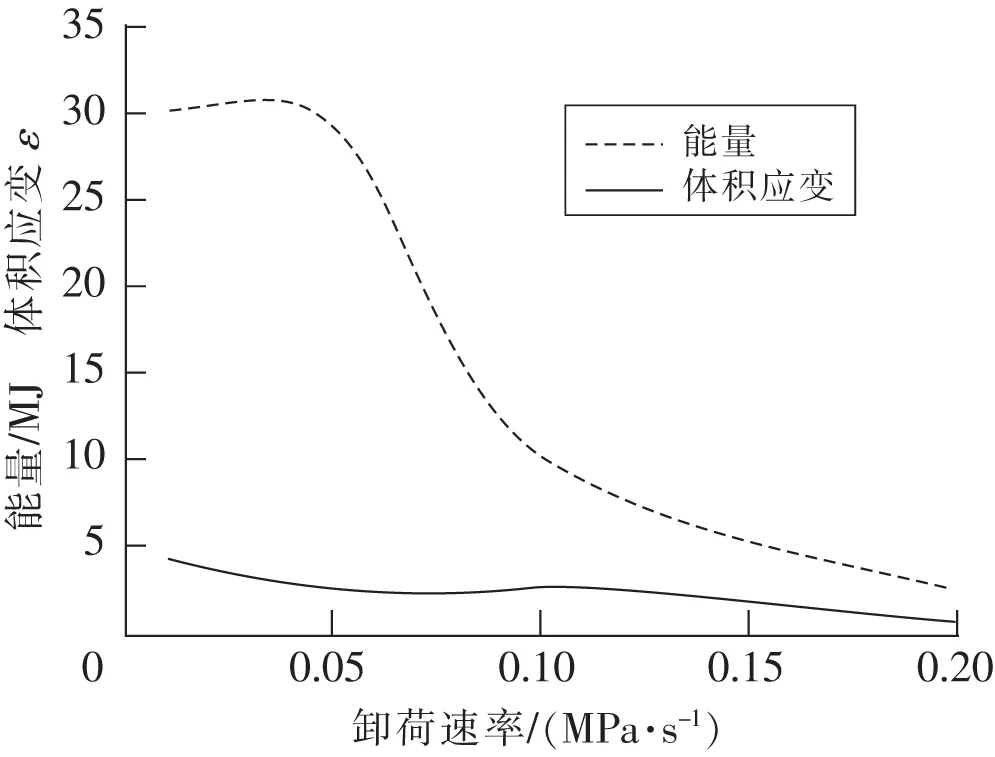

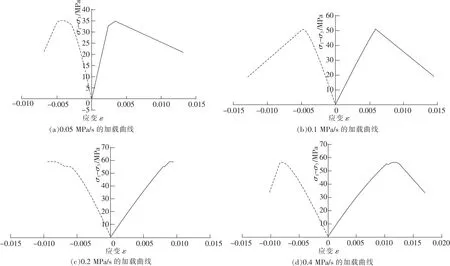

��ú�����Ĺ����У�����ú������һ��жΧѹ���߶��жΧѹ�Ĺ��̣�Ӱ��ú���ȶ��Ե������кܶ࣬�������������ٶȡ�ú����������϶����ȣ���С����Ҫ�����ڳ�ʼΧѹ���䣬ж�����ʸı������£�ú��������ݻ��о������ֳ�ʼΧѹ��20 MPa������£�̽��ж������Ϊ0.01 MPa/s��0.05 MPa/s��0.1 MPa/s��0.2 MPa/sʱ�������ݻ����ɡ�ȫӦ��Ӧ������������ͼ5��ʾ��

����ͼ5��֪��ͬж��������ú���ͷ�����������3��

ͼ4 ������Χѹ�仯����Fig.4 Variation trend of energy with confining pressure

�����������������Լ�ǿ����ж�����ʵı仯������ͼ6��ͼ7��ʾ��

����ͼ6��֪����ж�����������������£�������֮�½������Ӧ��Ҳ��֮�½�����ͱ�����ú��ʵ�������Ĺ����У�Χѹж������Խ�죬ú�����ͷ�����ԽС����֮��Ȼ������ʵ��жΧѹ�������������ݻ����ɴ�����ͬ��

��ͼ7��֪��ú���ķ�ֵǿ�ȺͲ���ǿ����ж�����ʵ����߶��½���������ж�����ʽϵ͵�����£�ú���ķ�ֵǿ�ȺͲ���ǿ�Ⱦ��ܴ����Ϊʵ��ú�����������ṩ��һ���IJο����塣

ͼ5 ��ͬж��������ȫӦ��Ӧ������Fig.5 Full stress strain curve under different unloading rates

ͼ6 ���������Ӧ����ж�����ʵı仯����Fig.6 Variation trend of energy and volume strain with unloading rate

ͼ7 ��ֵǿ�ȺͲ���ǿ����ж�����ʵı仯����Fig.7 Variation trend of peak strength and residual strength with unloading rate

3.3 ����ѹ�������������ݻ�����

ʵ��ּ��ģ������r�����������غ�������Χѹ��С�Ĺ��̡�������Ӧ����Χѹ���ﵽ20 MPaʱ���Բ�ͬ�ļ�����������������أ�������ͬ��ж�����ʽ���Χѹ������Ӧ��ȫӦ��Ӧ��������ͼ8��ʾ��

ͼ8 ��ͬ���������µ�ȫӦ��Ӧ������Fig.8 Full stress strain curve under different loading rates

��3 ��ͬж��������ú���ͷ�����

������ѹ���ʲ�ͬ������£�����ѹ���������������ƻ�ʱ��ѹ��Χѹ���غɼ���4��

��4 �������ʱ仯

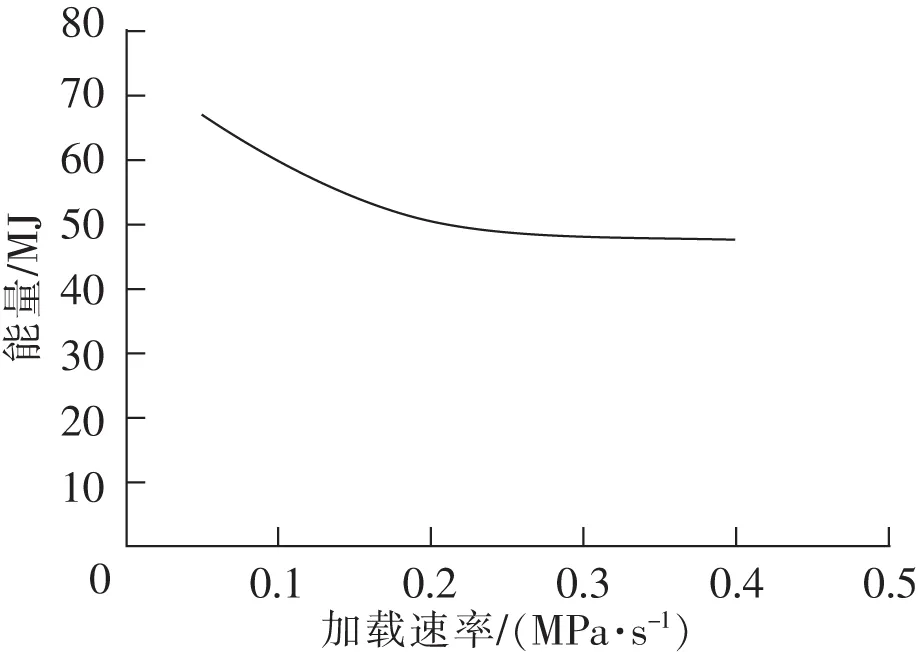

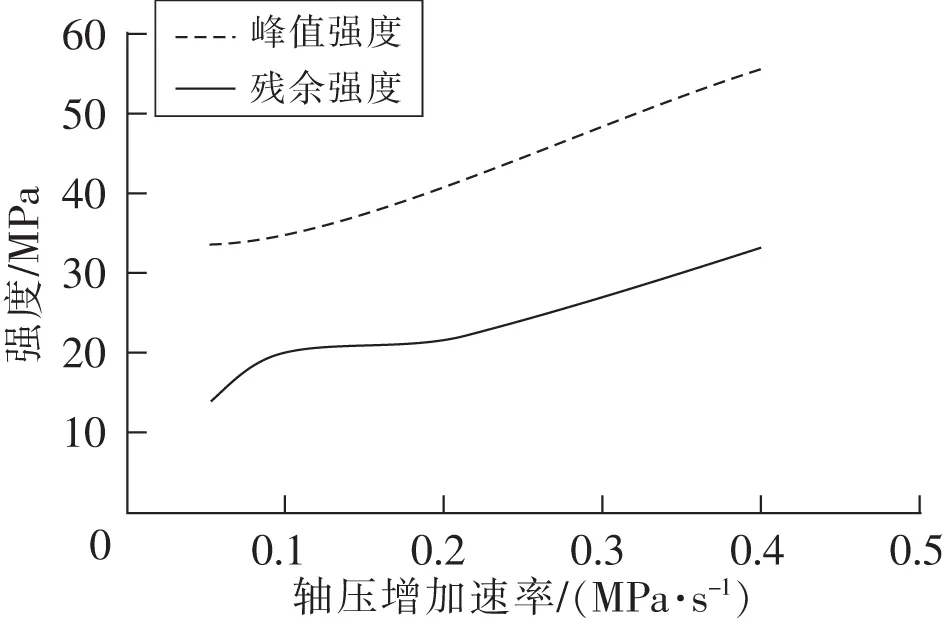

�����������������Լ�ǿ����ж�����ʵı仯������ͼ9��ͼ10��ʾ��

ͼ9 ��������ѹ�������ʵı仯����Fig.9 Change trend of energy with increasing rate of axial pressure

ͼ10 ��ֵǿ�ȺͲ���ǿ�����������ʵı仯����Fig.10 Variation trend of peak strength and residual strength with increasing rate

����ͼ9��֪������ѹ�������������������£�������֮�½�����ͱ�����ú��ʵ�������Ĺ����У���ѹ��������Խ�죬ú�����ͷ�����Խ��֮��Ȼ������ʵ�ʹ������������ݻ����ɴ�����ͬ��

��ͼ10��֪��ú���ķ�ֵǿ�ȺͲ���ǿ�����������ʵ����߶�����������˵����ѹ�������ʽϵ͵�����£�ú���ķ�ֵǿ�ȺͲ���ǿ�Ⱦ���С��

(1)ú����жΧѹ�Ĺ����У�ú�ﴢ��������Ჿ��ת�����������������������˺ͽϴֵ������Ŀ��ͷ�Ӧ���ܣ�ú�ﴢ���������2������������������֮�������ת����ú��������ʽ������������ú���׳��ȶ�������ú�崢���������Χѹ(����)Խ��������Խ����ΧѹԽ����������仯����Խ�졣

(2)�ڳ�ʼΧѹ���䣬ж�����ʸı������£�ú��ж������Խ�죬ú���ͷŵ�����ԽС���������ұ�Խ��ԽԶ�������غ�������Χѹ��С�Ĺ��̡��Բ�ͬ�ļ�����������������أ�������ͬ��ж�����ʽ���Χѹ����������ѹ�������ʵ�����������Խ���ƻ�ʱ��Χѹ����ѹǿ��Խ���ڼ��غ�ж�����ʲ��������£���ʼΧѹԽ��ú���ƻ��ķ�ֵ��ѹǿ��Խ����ѹ��ú������������Խ�ࡣ

(3)ú���ļ���ǿ�����Ų���ѹ����3����������ӣ�����ú���ƻ���IJ���ǿ�ȿ�֪��ú���ڷ����ƻ�����Ȼ���Գ���һ���ĺ��أ��Ҵ����������Ų���ѹ����3����������ӡ�

�������ϣ��������þ���Χ�ҵ�����ת�����ɣ�Ϊ���ӿ����ٶ�������ú������������Ŀ�ɽ��������ȹ���ʵ���ṩһЩָ����

����ϲ��ú��ж��ú�岻ͬ��ê�˲�����ú��֧��Ч����Ӱ���о���е��������(2022��2��)2022-05-12��ú��Ť����ж�ɲ���ֵģ�������е��������(2022��2��)2022-05-12ע�Ⱦ���Χú�������̵����ʱ仯����ģ���о��й���ҵ(2020��5��)2020-05-22������ú��֧�������о���չˮ��ˮ��챨(2019��12��)2020-01-02����������ú������Ӱ����������ú̿����(2019��4��)2019-05-05��ȫж�ɼ��ٶ������Ƽ��ٶ�����ټ���(2018��1��)2018-11-13��ȫж�ɼ��ٶ����ܲ��������о����ٶ�����ټ���(2018��2��)2018-11-09�ԡ����������Ϊͻ�ƿ�̽��ʱ����������ú��֮·�������㽭֮��Ϊ����ý����(2017��7��)2017-11-08���غ������¹���ú�嶯����Ӧ�����о�������ѧ(2015��9��)2015-02-17������̨ȫ����ú���Ч������������������һ�е��������(2014��3��)2014-03-01