����ʽ�������Ͳ��ջ�����������

������ ����ͨ ������ ����ϲ ������ ���ܾ�

(1.����ũҵ��ѧ��ѧԺ�� �人 430070��

2.ũҵũ�岿����������ũҵװ���ص�ʵ���ң� �人 430070)

�Ͳ����ҹ���Ҫ���������������Ϊ������������ܹ��������Ͳ˵���ֲЧ��[1]���Ͳ˲������Ͳ˶�����õ���;����ָ�ڶ������ڽ����������Ͳ�ժȡ���߲�ʳ�ã�

������Ͳ�ֲ����ȷ����磬�ɼ��������������������ǣ��ջ��Ͳ��ѣ�ʵ����������[2]���Ͳ���ʱժÿ����ɲ�3 000 kg���ϣ������Ͳ��Ѳ������ܴﵽ2 250 kg/hm2[3]������Ͳ˲���ÿ�������������ֵ����15 000Ԫ�����ҿ��Էḻ�߲˹����������ʱ���г����߿�ȱ�����߷�չDZ��[3-4]�����ֽ��Ͳ��ջ���ҵ��Ҫ���˹���ɣ��Ͷ�ǿ�ȴ�Ч�ʵ͡������ɱ��ߣ���Լ���Ͳ˲��÷�չ��������������Ҫ���õ��Ͳ��ջ��[2]��

�Ͳ����ڷǽ���Ҷ���߲ˣ������ջ�װ����ҵ��ʽ�IJ�ͬ�������߲��ջ���зǶ����ջ�Ͷ����ջ�������ʽ[5-6]�����зǶ����ջ���ṹ���������Ortomec��˾8400 ELECTRA������ʽ�߲��ջ�������ڸ�������˾4UM���߲��ջ��[7]��������߶�������Ͳ����ָ���ι�롢����ʽ������и���ҵ���жϾ���Ҷ�����ʹ��������ɼ����и�߶�һ��Ϊ200 mm���£���ҵ����һ��Ϊ1.2��1.5 m����Ҫ������ʩ������ֲ�ļ�ë�ˡ�С��ˡ����˵�Ҷ�˵��ջ����ջ����Ҫ���������������Ե��߲��ջ��絤��Asa-Life��˾PO-335�ʹ���ջ��[8]���ձ�������˾HL10�ʹ���ջ��������ֵ�[9]��ƵĴ�������ջ���ȣ�ͨ�����зֺ̡�Բ�̸�и���Լг����ͣ��Ե��л�˫�в��շ�ʽ���ж����ջ�[10]��

�����Hortechũ����˾SLIDE SW��Ҷ���߲��ջ����ʩӡ��[11]�з���«���ջ�����ο���[12]�з���«έ���ջ���������ö��зֺ̡�����ʽ��и�г����ͣ����ж��������ջ�

�Ͳ��Դ�����ֲΪ�������Լ2.0 m��Ϊ��֤����������ժʱӦ�����������˵�Ҷ����ѹ���磬����������߲��������Ͳ��ջ�

���ĸ����Ͳ��ջ�Ҫ�����һ������ʽ�������Ͳ��ջ������������ʽ�Ĵ�����ʵ�ֿ��������ߣ�������ʽ��ת�����и�װ�þֲ����зֺ̡���ת�и��Ͳ���ʵ�ֵ�Ҷ���桢�����ջ��Ͳ���ͨ���ջ������ѧ���˶�ѧ������̨������ȷ����̨���Žṹ���Ż��ջ���ҵ�����������и�Ч��������Ч��Ϊ����ָ�꿪չ������顣

1.1 �Ͳ��ջ�Ҫ��

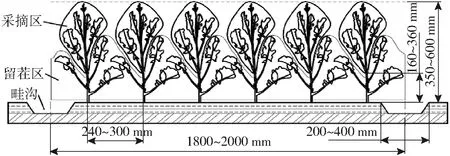

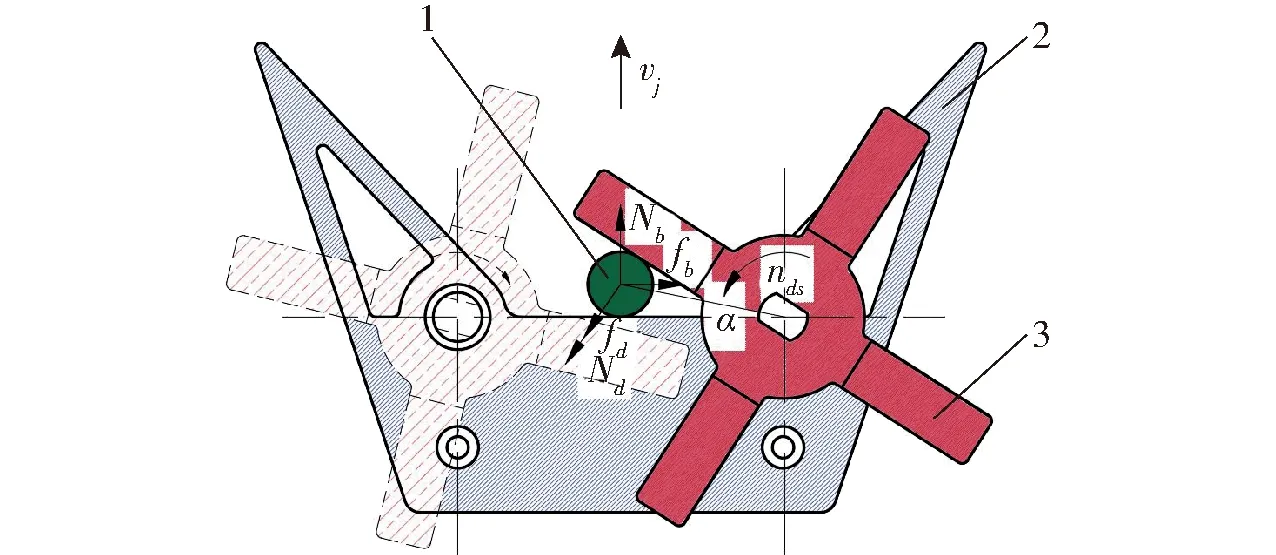

�Ͳ�Ϊ��ϵ��ˮ������������ε������Ͳ���ֲʱ��ƽ�����沢�����蹵������������ݴ���ˮ�ۼ�Ӱ��ֲ������[13-14]���Ͳ��ջ�״̬ʾ��ͼ��ͼ1��ʾ���Ͳ�����ʱ���������ջ�ʽ��ժȡ���������۾�Ҷ����������2Ƭ��Ҷ���������ò�ѿ�ȷ�����[2]�������Ͳ��ջ�״̬�������ջ����Ҫ�ṹ������ơ������Ͳ���ֲ¢�ࡢ�蹵���ȣ�ȷ���ջ�������Ϊ1 600 mm���Ĵ�����С��200 mm��

�����Ͳ���ֲ�о࣬ȷ���ջ�������и�װ���о�Ϊ240��300 mm��

�ջ�����߶�Ϊ160��360 mm��

ͼ1 �Ͳ��ջ�״̬Fig.1 Harvesting status of rapeseed stalks

1.2 �����ṹ

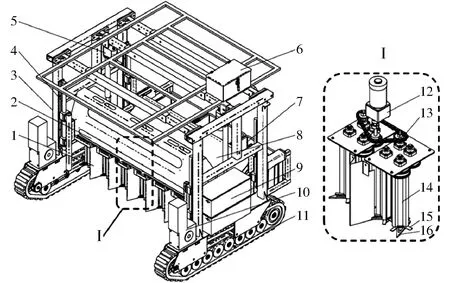

ͼ2 �Ͳ��ջ���ṹͼFig.2 Structure of harvester1.�ֺ��� 2.��̨ 3.���Ż��� 4.���� 5.��̨�����Ƹ� 6.������ 7.�ռ��� 8.���ʹ� 9.��� 10.������� 11.�Ĵ��ܳ� 12.��̨��� 13.������ 14.���� 15.Բ�̸ 16.��̶���

�Ͳ��ջ��������Ҫ������ʽ�Ĵ����̡���̨�������ռ�װ����ɣ���ͼ2��ʾ�������������1��ʾ������ʽ�Ĵ��������Ĵ��ܳɡ����ߵ������غ����Ż�����ɣ����Ż��ܿ��1 600 mm��ʵ�ֻ��߹���ʱ���������蹵�����ߣ������ջ������ѹ�Ͳ����Ĵ�ѡ�ÿ�150 mm�������Ĵ���

����ȡ����ʻ�Ͳٿ�λ�ã�����ң�ؿ��ƣ�����С�ջ�������ת��뾶������ģ��Ϊ��װHC05����ģ���STC89C52��Ƭ����ң�ز���ģ��Ϊ��T10����ң��������Чң�ؾ���100 m����̨���û����̨�����Ƹ˵Ȳ�����װ�����Ż����¡���̨��Ҫ��6����ʽ��ת�����и�װ�á�3̨��̨���������������̨�����ɡ�ÿ̨��̨���ͨ������������2������и�װ�ã��������и�װ�ö�����������ͨ���������װ�ü�࣬����Ӧ��ͬ�оࡢ�����Ͳ��ջ�

��1 �ջ����Ҫ��������Tab.1 Main technical parameters of harvester

1.3 ����ԭ��

�Ͳ��ջ������ԭ�����ջ����Ϊ�������������Ĵ��������蹵����һ���ٶ��н����Ͳ����ֺ���ѹҶ����£������ʽ��ת�����и�װ���в�����Բ�̸��̶�����������֧���и���ɼ����г֡����������ʹ��Ϸ���Ȼ���������ռ����У�����ջ�

�Ͳ����罫����֦Ҷ��ʵ�ֶ�β����ջ���ѡ����ջ�ͬ��ֲũ�ա������λ�Ʒ�ֵ��Ͳ�ʱ���ɵ����и����װ�ü�ࡢ��̨�߶ȵȹؼ������������ջ�ͬ�оࡢ�������߶��Ͳ���

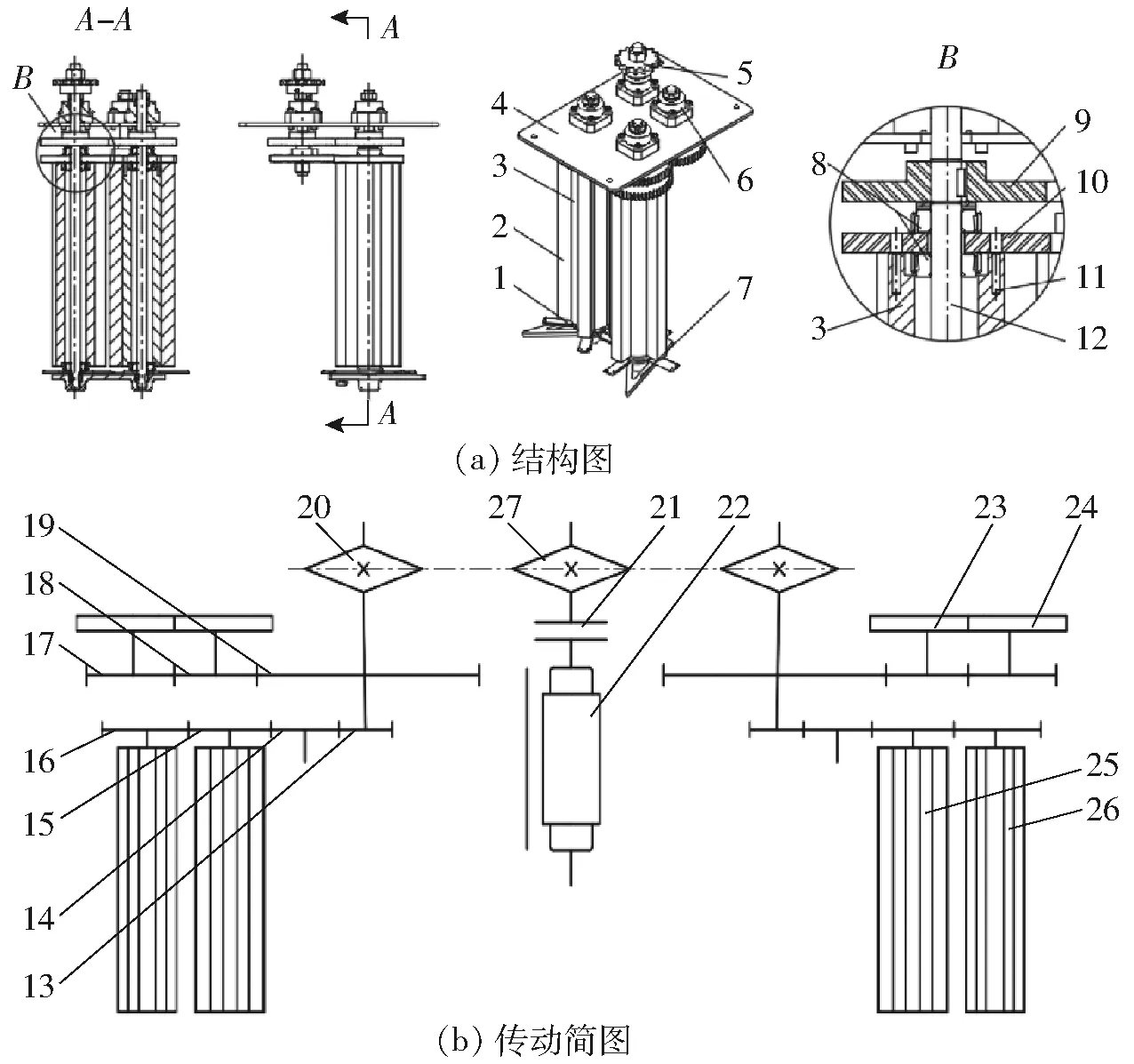

2.1 ��ʽ��ת�����и�װ�ýṹ���

�ջ����̨����ҵĿ��Ϊ�������ջ��Ͳ��ϲ����Ѻ���Ҷ�����ջ�������������װ�á�ʹ���Ͳ˾�������ֱ��������ʱ���������Ͳ�ֲ��ࡢ�о���ȣ�������������ֱ��������һ����ʽ�и��ʽ���͵���ʽ��ת�����и�װ�ã��Խ��յĽṹ��ʽʵ���Ͳ������ջ����и�װ����Ҫ�ɼ������������ݡ�Բ�̸����̶��塢���ֵ���ɣ���ͼ3a��ʾ��

ͼ3 ��ʽ��ת�����и�װ��Fig.3 Structure diagrams of vertical rotary header1.Բ�̸ 2.�������� 3.���� 4.��̨��װ�� 5.�������� 6.����� 7.��̶��� 8.Բ������� 9.��������� 10.������������ 11.�Թ����� 12.��� 13.�������֢� 14.�������� 15.�������֢� 16.�������֢� 17.����֢� 18.����֢� 19.�������֢� 20��27.���� 21.������ 22.��̨��� 23��24.Բ�̸ 25��26.����

�ջ���ؼ�������Ҫ�����ֺ������и�װ�á�����װ�õȣ�����ҵ��ʽֱ��Ӱ���ջ���Ĺ���Ч�����ջ�����õ��и�װ��������ʽ�ͻ�תʽ���֣���תʽԲ���и�װ�ýṹ����ҵ�������С���ٶȸߡ�����ƽ����������ҵʱ�ɽ��и�Ѻ��и���ҶƬ�Ӷ�������Ҷ���������Ͳ��ջ������յ�����״Բ�̵��ɷ�Ϊ������Բ�̵��������Բ�̵���������Բ�̵���[15-17]��Ϊ����Բ�̵�������Ŀ�����������������ջ����������ҵ��ѡ�ÿ�����Բ�̵���Ϊ��֤�����������ȣ����ٳ��[18]������������ʽѡ��˫Բ�̵���ÿ̨�����и�װ�õ�2Բ�̵��������ת����

����װ�����ջ���Ĺؼ�����֮һ��ֱ��Ӱ����ߵ����ͺ��ջ�Ч����Ϊ���ո�̨�ṹ�����о����һ����ʽ���������Ͳ��������������г֡����ͣ����Բ�̵�����ջ���ҵ��������װ��Բ�̵��Ϸ�����ͬ�ᣬ�����и�װ�õ�2�����������ת�����������������·�Բ�̵�ת����ͬ��

���ڸ�����ٶ�Ҫ��ϸߣ���������Ϊ����ת����

��ͼ���λ��ͬһ��ת���ߣ����иֱ�Ӱ�װ�ڸ���ϣ���������������ʽ��ͨ������Բ�������������װ���������ϣ�

�����������ת��ͨ�����ִ����Ĵ����Ȳ���ʵ�����ߵIJ�����ת��

Ϊʵ��ÿ�������Բ�̸����ת�����˶�Ҫ�����и�װ�ýṹ��ͼ3a��ʾ��Բ�̸ֱ�Ӱ�װ�ڸ����ࣻ

��������Բ�����������ָ������������ת����ɵļ����������������š������и�װ�õĴ���·����ͼ3b��ʾ��Բ�̸ͨ����װ�ڸ�����ĸ��������������ֱ������������ͨ��ֱ�Ӱ�װ�����Ϸ��ļ������֡��������������������ּ���������ɸı��������ֺʹ������ֳ����������������ٱȣ����������ٱ�i12�����������֢�ij���z1���������֢�ij���z2��ʾΪ

ȷ�������и�װ�û����ṹ��ʽ�������Ͳ�ֲ���������Լ��ջ�Ҫ��չ�ֺ�������ͼ�������ѧ���˶�ѧ�������Էֺ�������ͼ����ijߴ硢��ࡢ���ϡ�ת�ٵȹؼ��ṹ���˶����������Ż���

2.2 �ֺ������

�ֺ�����Ҫ����Ϊѹ���Ͳ���Ҷ�Ա������ˣ���£��ժ���Ͳ���Ҷ�����ι��Ч�����ֺ����ṹ��ʽ���ߴ������ֱ��Ӱ���ջ������ҵЧ����

ͼ4 �ֺ�����ҵԭ��ͼFig.4 Working principle of crop divider1.Բ�̸ 2.�ֺ��� 3.ѹҶ�� 4.£���� 5.�и���

�ֺ�����װ��ÿ�����и����װ��֮��ǰ�࣬ǰ��С��˴������ơ�������ҵЧ�����ֺ�������ҵ������ΪѹҶ����£�������и�������ͼ4��ʾ��ͼ�Ц�Ϊ�ֺ����ǣ�(��)��

vjΪ�ջ��ǰ���ٶȣ�m/s��

ffhΪ�ֺ������Ͳ�ҶƬ��Ħ������N��

NfhΪ�ֺ������Ͳ�ҶƬ����ѹ����N��

FfhΪ�ֺ������Ͳ�ҶƬ�����Ħ������N��ѹҶ����ÿ���Ͳ�����ֺ��������ͷֺ����ײ���������ɣ��������Ͳ�ҶƬ���ֺ����ָ�����ѹ���ֺ�����·���ʵ�ֵ�Ҷ������

£����Ϊ�ֺ������ڲ����и������������Ͳ���Ҷ����£���������и������Ա�֤�Ͳ���Ҷ˳��ι���̨��

�и���Ϊ�ι�����������ҵ������������������ø�Ȳ�������Ͳ���Ҷ�и

�ֺ����Ǧ��Ǿ����ֺ�����ҵЧ������Ҫ����[19]���ǦĹ�С�ᵼ�·ֺ����ߴ�����ǦĹ�����ᵼ�·ֺ�����ҵʱֲ�걻�ֺ����Ƶ����ֺ�����ҵԭ����ͼ4��ʾ�����Ͳ�ҶƬΪ�о���������ֺ̹������������Էֺ���ǰ���ٶȶ��Ͳ�ҶƬ��Ӱ�죬���ػ���ǰ���ٶȵķ�������ڷֺ������Ͳ�ҶƬ�����Ħ����Ffh������[19]

(1)

ʽ�Ц�fs�����ֺ������Ͳ�ҶƬ��Ħ������

ȡ�Ͳ�ҶƬ��ְ���ϵ�Ħ��������Χ��ľ�������֮���Ħ��������Χ��ͬ����fs=0.2��0.6����30��ܦġ�60�㡣Ϊ��ǿ�ֺ���ͨ���ԣ���Ӧ�ջ���ջ��о�240��300 mmҪ��ȡ�ֺ����ǵ��ڷ�ΧΪ30�㡫40�㣬���ȵ��ڷ�ΧΪ190��200 mm��

2.3 Բ�̸���

2.3.1Բ�̸�ṹ���

�����Ͳ�����۱������ԣ��������Ͳ�����ƽ��ֱ��ԼΪ15 mm������ֱ���������ϳ���С���ص㣻

����Ͳ��ļ���ǿ�ȡ�����ǿ�ȵ���������[20]������Բ�̸��ơ�

��Բ�̸�ߴ����ʱ������ֱ����������Чι��������͵���ת���������Ӷ�����ջ����ҵ�ȶ��ԣ�

��������ֱ�������ڸ�̨������Ϊ��Сʱ�������������档�����Ͳ˲��ֻ���ֲ�о��Ϊ240��300 mm[21-22]��Ϊ��Ӧ�Ͳ���ֲũ�գ�������켣����������С��240 mm��ͬʱΪ���Ӹ��Ч�и��������߸�̨����������������ֱ�����Ϊ120 mm������ƵĻ�תʽ˫Բ���и�װ����ҵԭ����ͼ5��ʾ�������������2��ʾ��

ͼ5 ��תʽ˫Բ���и�װ����ҵԭ��ͼFig.5 Working principle of double disc cutter1.Բ�̸�� 2.���������� 3.������켣�� 4.�Ͳ����� 5.Բ�̸��װ�� 6.Բ�̸��

2.3.2�Ͳ��и������ѧ����

�ջ����̨�и���̿��Լ�Բ�̸���̶�����ϼ����Ͳ����ѵ�ģ�ͣ��ù��̵���ѧ������ͼ6��ʾ��ͼ��ndsΪԲ�̸ת�٣�r/min��

��Ϊ�Ͳ����Ѽ���ʱ���и�ǣ�(��)��

NdΪԲ�̸�в����Ͳ�������ѹ����N��

fdΪԲ�̸�в����Ͳ�����Ħ������N��

NbΪ��̶�����Ͳ�������ѹ����N��

fbΪ��̶�����Ͳ�����Ħ������N��

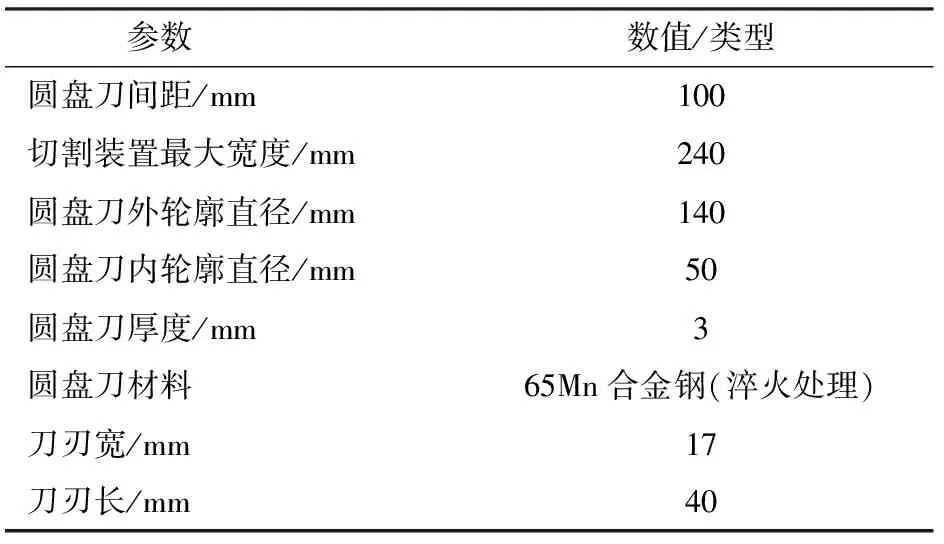

��2 ˫Բ���и�װ����Ҫ��������Tab.2 Main technical parameters of double disc cutter

ͼ6 �Ͳ����Ѽ��й��̵���ѧ����Fig.6 Mechanical analysis of stem shearing process1.�Ͳ����� 2.��̶��� 3.Բ�̸

��ͼ6��֪���Ͳ������ڱ����й�������Ҫ�ܵ���в���ѹ��Nd��Ħ����fd����̶������ѹ��Nb��Ħ����fb��Ϊ��֤�Ͳ������ڼ��й����в�����ƫ�ƣ���в����Ͳ����ѵ��������ػ���ǰ���ٶȴ�ֱ����ķ���ӦС�ڵ��ڸ�̶�����Ͳ����ѵ����Ħ����fbmax���ȼ��ڸ�п��������ת������֮��ļнǦ�ӦС�ڵ����Ͳ��������̶���֮��Ļ���Ħ���Ǧ£��������ǶȽ�С��90�㣬Ϊ������̣����������ǵ�����ֵ���㣬��

sin�á�sin��=��

(2)

ʽ�Ц̡����Ͳ��������̶���֮��ľ�Ħ������

����ͼ6�Ͳ��и���̸����̶�����Ͳ����Ѽ伸�ι�ϵ����֪�˹�����Բ�̸�п��������ת������֮��ļнǦü���ʽΪ

(3)

ʽ��r�����Ͳ����Ѱ뾶��mm

Ld����Բ�̸�пڿ��ȣ�mm

����Ħ����������������֪�Ͳ������ڼ��й����в��ᷢ�����ơ����и�������˫Բ�̸����ʽ���Ͳ����ѻ��Ƴ�һ�����и���ʱ����һ���ͼ����Ľṹ�Ὣ�Ͳ�����λ��������ԭ�и����ڣ�����Ч����©�

2.3.3Բ�̸�˶��켣����

Բ�̸���˶�Ϊ���䴫�����Բ���˶����ջ��ֱ���˶��ĸ����˶�������ˮƽ�����ϵĹ켣Ϊ����ߡ����ջ��ǰ������Ϊx��������ˮƽ���ϴ�ֱ���ջ��ǰ���������Ϊy��������������ϵ��Բ�̸ת�����ٶ�Ϊ��d�����п��˶��켣����Ϊ

(4)

ʽ��rd����Բ�̸�뾶��m

t����Բ�̸�˶�ʱ�䣬s

����˶��켣����ߣ�����״������Բ�̸��Բ���ٶ�vd���ջ��ǰ���ٶ�vj�ı�ֵ��(��ٶȱ�)�ˡ���и������Ҫ�ڰ��ߵ���͵㸽����������Ͳ��ٶ���С����Ϊ��֤�Ͳ����ѱ��жϣ�Բ�̸�ľ����˶��������㴦�����������ˮƽ���ٶȣ���Բ�̸�пڸ�����Բ���ٶȴ����ջ�����ǰ���ٶȣ���ٶȱȦ�>1����

vdmin=��drdmin=��rdminnds/30>vjmax

(5)

ʽ��vdmin����Բ�̸�пڵ�Բ���ٶȣ�m/s

rdmin����Բ�̸�п���ҵ�뾶��ȡ0.05 m

nds����Բ�̸ת�٣�r/min

vjmax�����ջ�������ҵ�ٶȣ�ȡ0.8 m/s

�����֪��Ϊ����©���Բ�̸ת��nds����СֵΪ122.3 r/min��

2.4 �������

2.4.1������������

�Ͳ����ѱ���жϺ��ջ��ﱻ�����������Ժ���ݼг�����������װ�ã��ڼ������������ջ���ײ����ȽӴ����ʹ��������Ͳ��ջ������۾�Ҷ���и�������е����ˣ�����������ͼ7��ʾ��

ͼ7 ���߹������̷���Fig.7 Working process analysis of harvester1.���� 2.�Ͳ�ֲ�� 3.�ֺ��� 4.���� 5.Բ�̸ 6.�Ͳ��ջ��� 7.����װ�� 8.�Ͳ�����

2.4.2�����ṹ���

������Ҫ�����������������ݡ��������ֵ���ɣ���ͼ8��ʾ�����ڼ������Բ�̸ʹ�ã���ṹ�ܵ�Բ�̵���״�ߴ�Ȳ�����Ӱ�죬���ǵ�������װ��ṹ�ͼ������ӷ�ʽ�����������������⾶ȡ60 mm��

ͼ8 �����ṹͼFig.8 Structure of grabbing and throwing rollers1.���������� 2.�������� 3.�������� 4.����λ��� 5.��˨���Թ����� 6.����λ���

�������������ݵķֲ������Ӱ��������Ͳ��г����ͼ��������Ͳ����˵���Ҫ���أ������ݷֲ����ܣ������ݶ��Ͳ���Ħ����С�Ҷ��Ͳ�����ֱ���仯�ϴ��Ʒ����Ӧ�Խϲ���Ͳ��ߴ�ϴ�ʱ����ҶƬ������ѹ����������������ι���̨�Ӷ���ɸ�̨������

�����ݷֲ�����ϡ�裬��Թ��г�����С�����Խ��Ͳ��Ե˽Ӵ�����������������װ���Ϸ��Ӷ����Ӿ�Ҷ���ˡ������Ͳ������������Բ���������[20]��ѡ��4��������ݾ����ڼ����������Ľṹ��ʽ��

���ǵ��������ݵİ�װ��ʽ���ṹǿ�ȺͶ��Ͳ����ѵ�����������������������⾶�ߴ�Ϊ60 mm���������Ϊ100 mm�Ƚṹ���������ǵ��������Ͳ�����ƽ��ֱ��ԼΪ15 mm����������[20]��Ϊ��֤������Ч�г��Ͳ����������ݼ侶�����ӦС���Ͳ�����ֱ����ͬʱΪ�������������������������һ��������϶Ӧ�����Ͳ�����ֱ��������������ݺ��Ϊ12.5��25 mm��

Ϊ��֤�Ͳ�����˳�������ټ�������������ҶƬ�ϵļг����Լ���ҶƬѹ�𣬼������ݼ������м�϶������������ݺ��Ϊ15��32 mm��Ϊ���ڼ������ݼӹ����죬ѡ�ú�ȡ����Ⱦ�Ϊ20 mm�ĺ�������Ϊ�������ݡ�

Ϊ�������м������������ݳߴ���Ƽ�����ѡ��չ��������������ѧ��������ͼ9��ʾ��ͼ��O0Ϊ�Ͳ��ջ����ģ�

O1Ϊ�����г��Ͳ��㣻

G1Ϊ�Ͳ��ջ�������N��

Nd1Ϊ����Ͳ��ջ�֧������N��

Fd���������N��

L0Ϊ�Ͳ��ջ���������ֱ���룬m��

L1Ϊ�����г��Ͳ�������ֱ���룬m����ʽ��ת�����и�װ����ҵʱ������Բ�̸�����Ͳ����ѣ���ʱ�Ͳ��ջ��ڸ������Fd��������������G��ʱ����ת��

��������Ͳ�����������̶�����ϴ�ʱ������̶����γɼ������ã���������ȫ�жϡ�������ʽ����������õĺ���������ݼг��Ͳ����ѵ�O1���ڱ����Ͳ����˵�����½��Ͳ�������������װ�á�

ͼ9 ��������������ѧ����Fig.9 Mechanical analysis of working process of grabbing and throwing rollers

�����г��Ͳ�ʱ���豣֤�������ݶ��Ͳ��ļг����ܹ�ʹ�ջ��ﱻ����������װ���Ϸ���ͬʱ��Ҫ�����������ѹ���ջ��ͨ���������������������Ͳ����˶��켣�ɵã��������Ͳ��ܵ�������Ҫ�����Ͳ���������mcg���������ݶ��Ͳ�ֲ���������Fc���������Fd��Ϊ�����Ͳ��ڼ������з�������Ӷ���ɾ����ظ���ջ������ˣ��������ݶ��Ͳ�ֲ���������Fc����ֱ���Ϸ���(y������)�ϵķ���Ӧ�����Ͳ�����mcg����

Fcy>mcg

(6)

ʽ��Fcy�����������ݶ��Ͳ�ֲ�������������ֱ�����ϵķ�����N

mc�����Ͳ��ջ�������kg

g�����������ٶȣ�ȡ9.8 m/s

�������ݶ��Ͳ�ֲ���������Fcy��ҪΪ�������ݷ��������α���Ͳ������ĵ���������ʽΪ

(7)

ʽ��Ec�����������ݵ���ģ����MPa

d�����Ͳ�����ֱ����mm

Ϊ��֤�Ͳ���˳���������Ͳ����Ѳ�����������������ݶ��Ͳ�ֲ���������FcyӦ���ڵ����Ͳ�����mcg��С�ڵ����Ͳ����Ѿ���ƽ����ѹ��Fj����

(8)

���ĺ�����������������ϲ�����������飬ѡ��Ӳ��Ϊ35��(HB)�ĺ�������Ϊ�������ݡ�

2.4.3�����˶�ѧ����

��Բ�̸�����Ͳ����ѵĹ����У��Ͳ����ѱ����Ϻ�����Բ�̸��Լ���Ͳ��ջ���������O0��ת���Ͳ��ջֵ��ٶ���Բ�̸�и��λ�����ٶ���ͬ��������ڻ��ߵij��ٶȿ���Բ�̸�и�λ�����ٶȱ�ʾΪ

(9)

ʽ��vc0�����Ͳ��ջֵ�������ջ�����ٶȣ�m/s

dd0����Բ�̸�и��λ�ð뾶��m

Ϊ�������̡����ͼ��㸴�Ӷȣ������о����ڽ�����ѧ����ʱ����Ҷ��ѧ���ý���������ģ�ͼ�Ϊ��Բ�����Բ��[9,12]�������ڼ��������Ͳ�ҶƬ�������г֡�ѹ����������϶�У��Ͳ�����Ҫ��ѧ��������Ϊ���ѶԼ��������ã����о����Ͳ���Ϊ���������ֲ����ȡ����������ֲ������ȵķǾ���Բ���壬����Ͳ�����λ�ý�����ѧ���˶�ѧ������ͨ���Ͳ�����λ�ò������飬�õ��Ͳ�ƽ���߶�Ϊ596.4 mm��ƽ������λ��Ϊ227.6 mm��ƽ������λ��Ϊֲ���²������и�λ��2/5ֲ�곤�ȴ����ж�˲���Ͳ��ջ�������������ת�˶�������Ϊ�˹����Ͳ��ij�ʼ������Ҫ���ڿ˷���������Ħ���������������������غ㶨�����Ͳ��ײ��ܹ������˶������߶Ⱥ������ת��������ɱ���Ϊ

(10)

ʽ��Fcyg�����Ͳ��������Ħ������N

hc1�����Ͳ��ײ������˶������߶ȣ�m

xcx�����Ͳ������ת�������룬m

��֪�Ͳ���ת���̵ĵײ�����λ����Ҫ�ܼ����г��Ͳ�λ�á��Ͳ��������ת�١���и�λ�á��Ͳ��������Ħ������Ӱ�졣

�Ͳ��������ת�˶��������ջ���г�������������װ�ã��Ͳ��������������ˮƽ�ٶȵ��ڼ�������������������ٶȵ�ƽ���˶�[14]���׳�˲���Ͳ�ˮƽ���ٶ�Ϊ

(11)

ʽ��vc1�����Ͳ�ƽ���˶�ˮƽ���ٶȣ�m/s

vg����������������ٶȣ�m/s

dg0�������������ֱ����m

�Ͳ���ƽ���˶���ײ������䵽���ʹ��Ϸ��������Ͳ��˶��ٶȽ�����Ϊ������̺���ҶƬ�����ѵ��ܵ��Ŀ������������Ͳ��г�ԭ����Ϊ����ϵԭ�㣬����ǰ������ķ�����Ϊx����������������Ϊy���������д�ƽ���̵��˶�ѧ������ɵõ��Ͳ�λ�ơ��ٶȱ仯����

(12)

ʽ�Ц�s�������ʹ���ˮƽ���нǣ�(��)

xds��������������ʹ�ǰ��ˮƽ���룬m

xc1�����Ͳ��Ӵ����ʹ���ˮƽλ�ã�m

yc1�����Ͳ��Ӵ����ʹ�����ֱλ�ã�m

t1�����Ͳ�ƽ�������ʹ���ʱ�䣬s

vc2�����Ͳ�ƽ�������ʹ�ʱ�ٶȣ�m/s

��ʽ(9)��(12)�ɵ��Ͳ��ײ��Ӵ������ʹ���ˮƽ����ֱλ��Ϊ

��֪���Ͳ����������ͺ������λ�úͼ���ת�١��ת�١�����ֱ������и�λ�á��Ͳ�����������������ʹ�ǰ�����λ��ˮƽ���롢���ʹ��ǶȵȲ���������أ����Ͳ��������Ħ�������Ͳ����ȵȲ����ʸ���ء�

3.1 ����װ���뷽��

3.1.1�Ͳ��ջ�����̨

Ϊ�����ջ���ҵ�����Ż�����Ͳ��ջ�����̨������������͵����ֲ��г����������������Ž�װ�á����ͲĿ�ܵ���ɵ��Ͳ��г�����װ�ú��ɼ����������������ͲĿ�ܵ���ɵĸ�̨����װ�������֣���ͼ10��ʾ��

ͼ10 �Ͳ��ջ�����̨ʵ��Fig.10 Object pictures of harvest test bench1.���͵�� 2.��̨����װ�� 3.���� 4.Բ�̸ 5.�������� 6.�Ͳ� 7.ֲ��г���

3.1.2��������뷽��

̨��������ũҵũ�岿�Ͳ�ȫ�̻�е�����л��ؽ��У��������ѡ�û�����������ֲ��ʨɽ��Ʒ���Ͳ�[23-24]���ɼ�ʱ��Ϊ���ֺ�64 d���ڽ�������ǰ�����Ƚ��Ͳ�ȥ����ϵ���г����Ͳ��ջ�����̨���Ͳ�ֲ��г����Ϸ�������ת���ǡ������ǵ��豸��չ̨�����顣

(1)��������ѡ��

����ʵ����ҵ�����У���תʽ��ͼ�����ˮƽ�����ϵ��˶��켣Ϊ����ߣ�����ߵ���״�ܹ����Ͳ��и��������Ч�������ϴ�Ӱ�졣��������ߵ���״�ֱ���Բ�̸ת��������н��ٶ��ٱȡ�����ת��������н��ٶ��ٱȾ��������ȷ��Բ�̸ת�١�����ת�١�ι���ٶ�(�����н��ٶ�)Ϊ�������ء�

(2)�ջ���������ָ��

Ŀǰû�пɲο����Ͳ��ջ���ջ��������������ο��ײˡ����ˡ���еȾ�Ҷ���߲��ջ����������[9,17,25]�����ǵ��Ͳ�����ջ�Ͷ���;���õ���ֲ��״[26-27]�������Ͳ����ջ�Ҫ�����乤�������Ͳ��ջ��ľ����жϱ�Kq����������������Kc���п�ƽ����Kk���������ͳɹ���Kp����ҶƬ������Ky������������Kg��Ϊ�������أ�������㷽����ָ��Ϊ

(13)

ʽ��Tq�����Ͳ��ɹ��ж�������

Tz�����Ͳ���������

(14)

ʽ��Tzc�����Ͳ�������������

Tsc�����Ͳ����������������

(15)

ʽ��Ss�����Ͳ��п����������mm2

Sz�����Ͳ��п��������mm2

(16)

ʽ��Tp�������׳ɹ����Ͳ�������

(17)

ʽ��Tzy�����ɹ������Ͳ�ҶƬ��������

Tsy�����ɹ������Ͳ�ҶƬ�������������10%��������

(18)

ʽ��Tsg�����ɹ������Ͳ��о��������������20%���Ͳ���������

Tzg�����ɹ������Ͳ���������

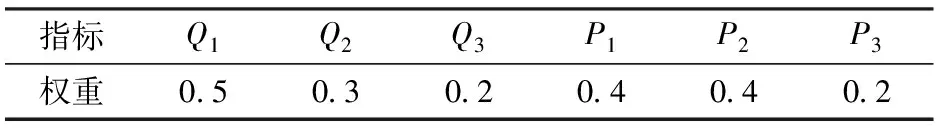

�ۺϾ����жϱȡ��п�ƽ���ȡ�����֦�������Ϊ�и�Ч��Q���������ͳɹ��ʡ��Ͳ����������ȡ��Ͳ�ҶƬ������Ϊ����Ч��P�������Ͳ��ջ�Ҫ�������ָ��Ȩ�أ��õ��и�Ч��Q�ͼ���Ч��P����ѧģ�ͷֱ�Ϊ

(19)

ʽ��Qi�����и�Ч��Ȩ��

Pi��������Ч��Ȩ��

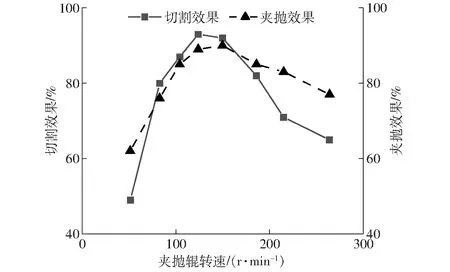

�����Ͳ�����Ʒ���Լ������������˺�����Ҷ���ջ�Ҫ��[2,26]���ջ��Ͳ�ʱ����Ҫ��֤���������жϡ��ջ�����������ʹ��ϣ���α�֤��ժ����ҶƬ�;�������������ҶƬ������ͬʱ����Ҫ����ƽ�룬��˸����и�Ч���ͼ���Ч���ĸ���Ȩ��ȡֵ���3��ʾ��

3.2 �����������������

��չ�ջ���ҵ�����Ż�����Ԥ���飬������Ч�������������ۣ�����ȷ���ת��Ϊ190 r/min������ת��Ϊ127 r/min��ι���ٶ�Ϊ0.64 m/sʱ�ջ�Ч���Ϻã��Դ�Ϊ���ݽ�һ����չ̨�ܵ�����������������顣

��3 �ջ�����ָ��Ȩ��Tab.3 Weight value of each evaluation index

��ѡȡ��3���������طֱ���е��������飬���������ضԸ�̨�и�Ч���ͼ���Ч����Ӱ�졣�ڶ�ij�����ؽ��е���������ʱ���������ΪԤ����Ч���ϼ�ֵ��ÿ�������ظ�5�Σ�ȡƽ��ֵ��

�ת�ٶ��ջ�Ч����Ӱ����ͼ11��ʾ���ڼ���ת�ٺ�ι���ٶȺ㶨������£���̨�и�Ч���ͼ���Ч����ת�ٵ������ȿ��������������͡����ת��С��155 r/minʱ����̨�и����Ч���ϲ������˶��켣���۲�����װ����ҵЧ�����ִ�ʱ����©�������ת�ٴ���198 r/minʱ�и�Ч���Ϻã�����ת�����Ӽ���Ч�����½����۲췢�ָת�ٽϿ�ʱ�Ͳ��ջ����ױ������������̶����϶������ظ��и

ͼ11 �ת�ٶ��и�Ч��������Ч����Ӱ��Fig.11 Influence of cutter rotation speed on cutting and conveying

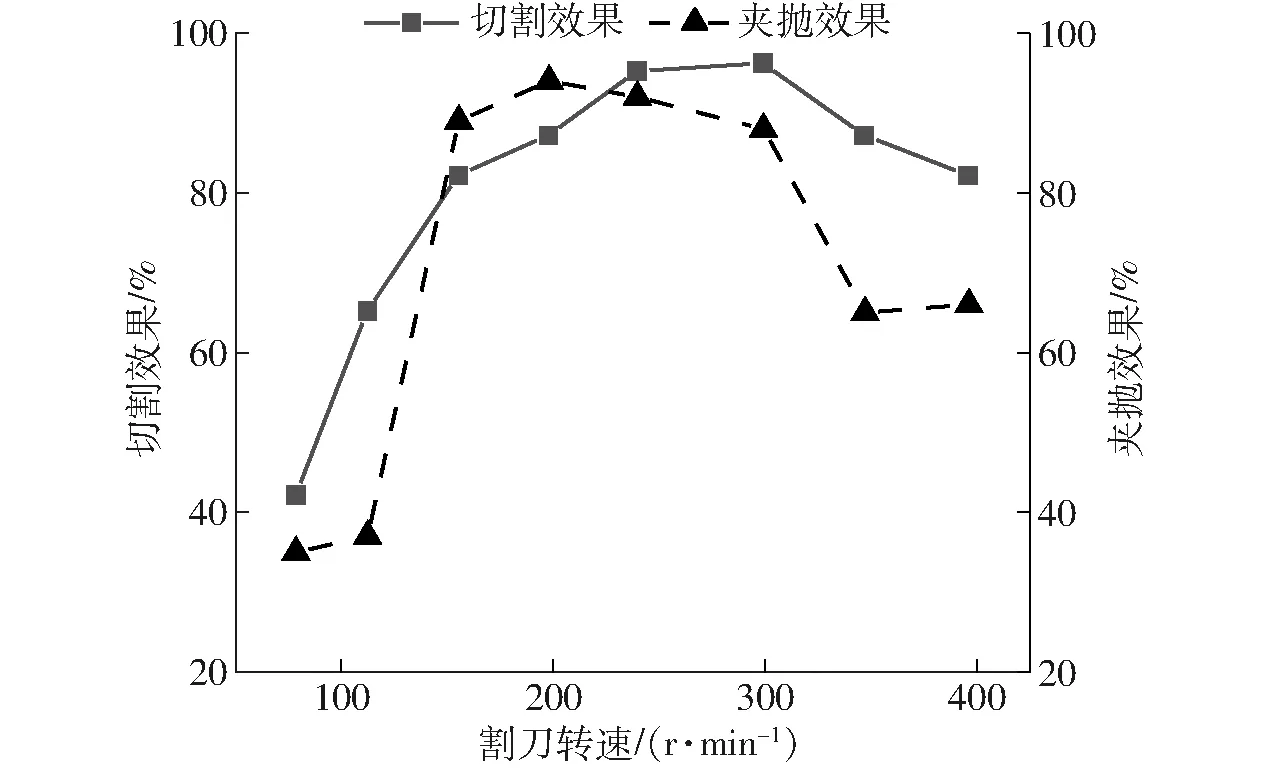

����ת�ٶ��ջ�Ч����Ӱ����ͼ12��ʾ���ڸת�ٺ�ι���ٶȺ㶨������£���̨�и�Ч���ͼ���Ч�������ת�ٵ����������ߺ͡��۲�������֣�������ת�ٽ���ʱ��̨���������Ϊ���أ������Ͳ��ظ��©�ף�

������ת��С�ڸת��ʱ���Ͳ��и����Ч���Ϻã����Ͳ��ջ����ܹ����ո�̨�˶�ѧ����Ԥ����������и�����̣�

������ת��Զ���ڸת��ʱ���Ͳ����ȱ������������ף�����о����ио���ھ��ѽ��������϶�������Ͳ��ظ���ջ������ˡ�

ͼ12 ����ת�ٶ��и�Ч��������Ч����Ӱ��Fig.12 Influence of grabbing and throwing roller speed on cutting and conveying

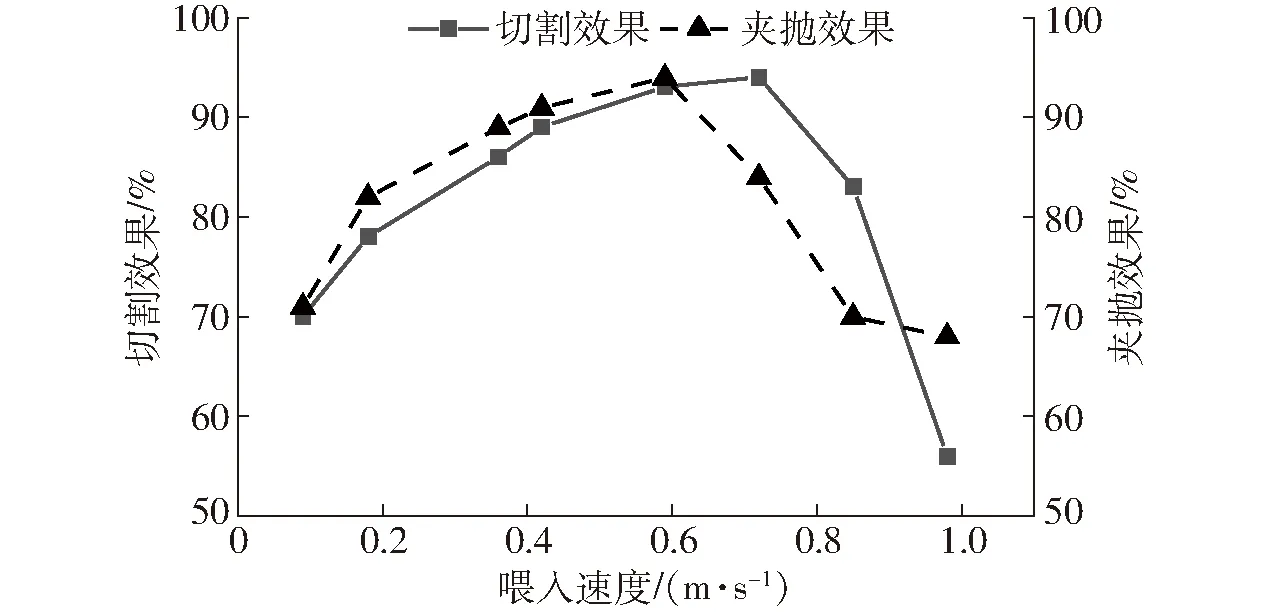

ͼ13 ι���ٶȶ��и�Ч��������Ч����Ӱ��Fig.13 Influence of feeding speed on cutting and conveying

ι���ٶȶ��ջ�Ч����Ӱ����ͼ13��ʾ���ڸת�ٺͼ���ת�ٺ㶨������£���̨�и�Ч���ͼ���Ч����ι���ٶȵ������Ȼ�����������ٽ��͡��۲������֪����ι���ٶȽ���ʱ���Ͳ�ֲ���ظ�����϶ࣻ

��ι���ٶȽϿ�ʱ������©����иƤ��

��̨�ջ��������������ڸת��Ϊ160��300 r/min������ת����80��150 r/min��ι���ٶ�Ϊ0.30��0.70 m/sʱ���ջ�����̨�и�Ч��������Ч���Ϻá�

3.3 ���������������

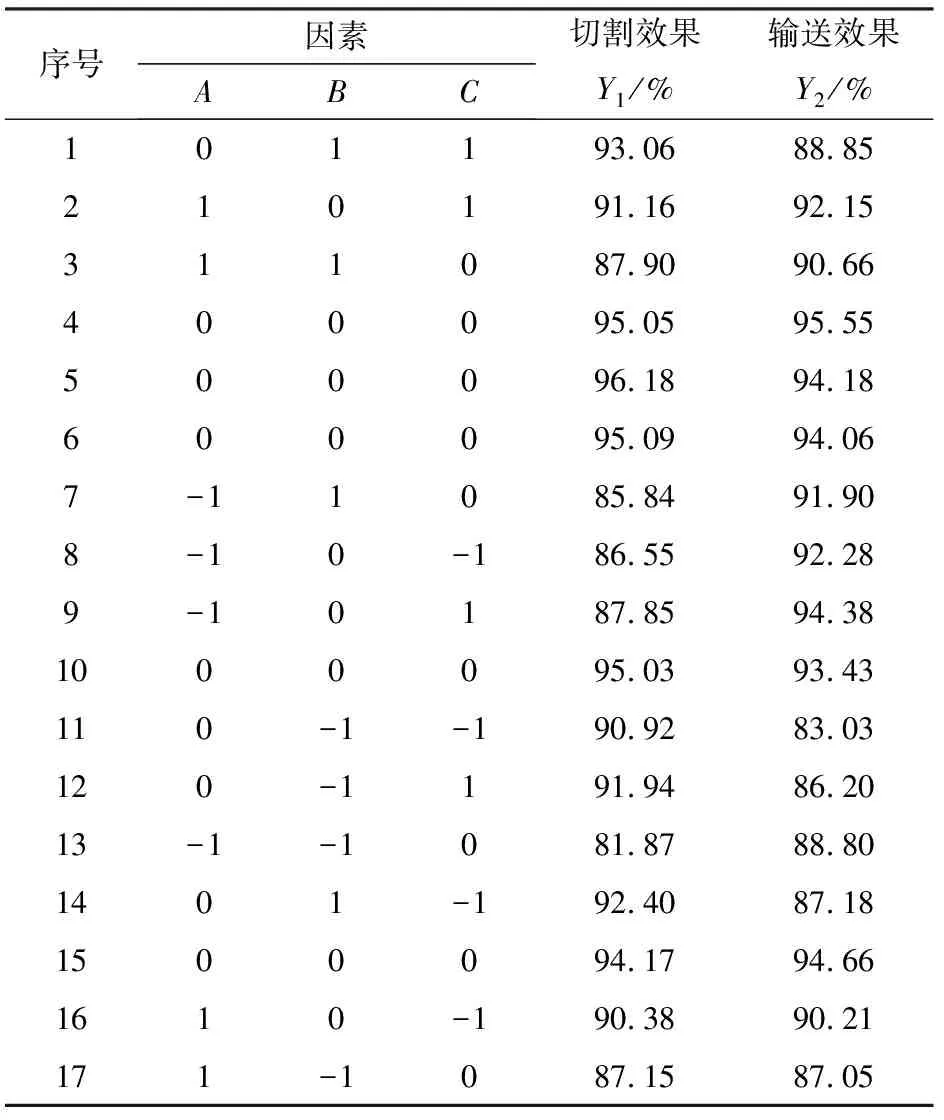

���ݵ��������������Ըת�١�����ת�١�ι���ٶ�(����ǰ���ٶ�)Ϊ�����Ա��������и�Ч��������Ч��Ϊ����ָ�꣬�õ���������ˮƽ�����������ر������4��ʾ��

��4 ����̨�����������ر���Tab.4 Factor code for orthogonal experiments

����������Ʒ�������Design-Expert�õ��������������չ���飬ÿ�������ظ�5�β�ȡƽ��ֵ�����������5��ʾ��A��B��C�ֱ�Ϊ���ظת�١�����ת�١�ι���ٶȵı���ֵ��

����Design-Expert������BBDģ�飬�����õ��и�Ч��������Ч���Ķ��ζ���ʽ�ع�ģ��Ϊ

(20)

�ջ�̨���ջ����鷽��������6��ʾ�������ع�ģ�͵�Pֵ��С��0.000 1�������ع�ģ�ͼ�������ʧ�����P>0.05�������ع�ģ��ʧ�����������ϳ̶ȸߡ��ת�١�����ת�ٶ��и�Ч����Ӱ�켫�������ת�ٺͼ���ת�ٵĽ������ö��и�Ч����Ӱ����������������Ӱ�첻�����������ض��и�Ч����Ӱ���ɴ�СΪ�ת�١�����ת�١�ι���ٶȡ�����ת�١�����ǰ���ٶȶ��и�Ч����Ӱ�켫�������ת�ٶ��и�Ч����Ӱ����������������Ӱ�첻�����������ض��и�Ч����Ӱ���ɴ�СΪ����ת�١�

��5 �Ͳ��ջ�����̨����������Tab.5 Results of orthogonal experiments

����ǰ���ٶȡ��ת�١�

��6 �и�Ч��������Ч���������Tab.6 ANOVA for cutting effects and conveying effect

��ģ�͵IJ���������и�Ч��������Ч���Ķ��ζ���ʽ�ع�ģ��Ϊ

(21)

����Design-Expert����BBDģ����������ݴ��������ƶ�����ָ��Ӱ�������Ľ������õ���Ӧ�棬��ι���ٶ�Ϊ0.56 m/sʱ���ת�١�����ת�ٵĽ������ض��и�Ч��Ӱ����ͼ14��ʾ��

ͼ14 �ת�١�����ת�ٵĽ������ö��и�Ч�� Ӱ�����Ӧ��(Xw=0.56 m/s)Fig.14 Influence of interactive factors on cutting effect

��ͼ14��֪������ת��һ��ʱ���и�Ч�����Ÿת�ٵ����Ӷ������Ӻͣ��ת��Ϊ240 r/minʱ���и�Ч��ȡ�����ֵ��

�ת��һ��ʱ���и�Ч�����ż���ת�ٵ����������Ӻͣ�����ת��Ϊ120 r/minʱ���и�Ч��ȡ�����ֵ��

�����Ͳ��ջ�������Ҫ�����и�Ч��������Ч�����������ΪĿ�꺯�������ת�١�����ת�١�ι���ٶȵ������ϣ�Լ������Ϊ

(22)

����Design-Expert�������ؽ������Ż���⣬�õ��������������Ϊ���ת��Ϊ234 r/min������ת��Ϊ120 r/min��ι���ٶ�(����ǰ���ٶ�)Ϊ0.56 m/s���ۺ��ջ�Ч����ѣ���ʱ�и�Ч��Ϊ95.43%������Ч��Ϊ94.81%�������ҵЧ��Ϊ0.41 hm2/h��

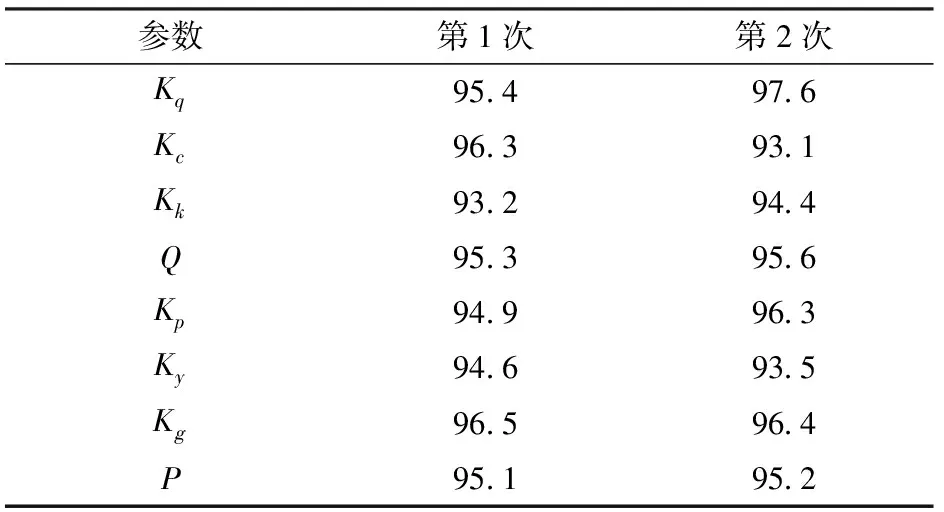

2021��12�º�2022��2���ڻ���ũҵ��ѧũҵũ�岿�Ͳ�ȫ�̻�е�����л���������ֱ��������ջ�������֤���������Ϊ������ʨɽ���������������Ż����Ϊ�������������黷��������Ч����ͼ15��ʾ��������������7��ʾ��

����ջ��������������ջ���и�Ч���ɴ�95.6%������Ч���ɴ�95.2%���ջ�Ч�����á�

(1)�����һ������ʽ�������Ͳ��ջ����ȷ�����ջ���������ṹ����Ҫ�����������ջ����Ҫ�ɸ�̨�������ռ�װ�á�����ʽ�Ĵ�������ɣ�ʵ���Ͳ��и���ס����͡��ռ����ܡ�

ͼ15 ����ջ���ҵFig.15 Field harvest

��7 ����ջ���ҵ���Tab.7 Field harvest operation result %

(2)�����һ����ʽ��ת�����и�װ�á�������ջ���ĸ�̨���ֺ�����Բ�̸�������Ľṹ��ƣ�����Ͳ��ļ��С����ס������̽��������۷�������չ��Բ�̸�ͼ�������ơ���ѧ���˶�ѧ������ȷ���������������Ϊ100 mm�����ʽΪ�⾶Ϊ140 mm�Ŀ�����Բ�̵���������ʽΪ��లװ4��35��(HB)�������Ĵ�60 mm��������

(3)��ơ�����Ͳ��ջ�����̨�����и�Ч��������Ч��Ϊ����ָ�꿪չ������������������飬�����õ��ڸת��Ϊ234 r/min������ת��Ϊ120 r/min��ι���ٶ�(����ǰ���ٶ�)Ϊ0.56 m/sʱ�ۺ��ջ�Ч����ѣ��и�Ч��Ϊ95.43%������Ч��Ϊ94.81%��

(4)�Ͳ��ջ������ɹؼ��������������������ӹ�����������ջ���֤���顣���������������ջ�������ҵЧ��Ϊ0.41 hm2/h���ջ��жϱ�Ϊ97.6%����������������Ϊ93.1%���п�ƽ����Ϊ94.4%���������ͳɹ���Ϊ96.3%���Ͳ�ҶƬ������Ϊ93.5%���Ͳ�����������Ϊ96.4%���ۺϺ��и�Ч��Ϊ95.6%���ۺϺ�����Ч��Ϊ95.2%��

����ϲ�� ���ջ������ �����ޮ����Դ����(2022��12��)2023-01-03ˮ�����ѽӴ����������ⶨ����ɢԪ����궨����ũҵ��ѧѧ��(2022��3��)2022-07-07��֮�����й�ũ��Ƽ�(2021��12��)2021-12-28��ˮ�Ͳ��ӹ���������Ϸ�ũҵ(2021��28��)2021-12-25������� �ջ���г�����ת�ͽ���ũ����(2020��5��)2020-10-26������û�гԹ�����Է(2020��3��)2020-04-21������2020 ����ũ��Զ�����ջ��ֵ���ڴ�">��������������������2020 ����ũ��Զ�����ջ��ֵ���ڴ��ӱ�ũ��(2020��1��)2020-01-11���Ӿ����и���ѧ�������������ũҵ��еѧ��(2019��4��)2019-04-29ʩ������ʩ��Ƶ�ʶ��ϻ���ޣ����ֱ�������ȵ�Ӱ�����������Ͽ�ѧ(2018��5��)2018-06-13����������ʳ��ѧ(2017��4��)2017-05-03